GE Hitachi's Answer to Nuclear Waste

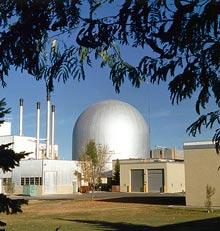

The Idaho National Laboratory’s Experimental Breeder Reactor, a sodium-cooled nuclear reactor decommissioned in 1994, was a predecessor of a new design from GE Hitachi Nuclear Energy.

By Kevin Bullis

Technology Review

GE Hitachi Nuclear Energy, one of the world's biggest providers of nuclear reactors, says it has an alternative to burying nuclear waste at Yucca Mountain in Nevada, the proposed waste repository that the Obama administration has said is now "off the table." Based in Wilmington, NC, GE Hitachi wants to use nuclear waste as a fuel for advanced nuclear power plants, significantly reducing the volume of waste and the length of time that most of the waste needs to be stored.

National labs in the United States and GE have been developing the technology over the course of a few decades, but in recent years the company "put it on the shelf" because of a lack of U.S. interest in reusing nuclear waste, says Eric Loewen, chief consulting engineer for advanced plants at GE Hitachi. The technology involves separating nuclear waste into different types of useable fuel, some of which can power conventional nuclear power plants, and some of which require advanced "fast neutron" reactors, which are being used in power plants elsewhere but not in the United States.

The company hopes a new blue-ribbon panel appointed by the Obama administration to find a new nuclear-waste solution will recommend the use of their system. Steven Chu, U.S. Secretary of Energy, has expressed support for different kinds of nuclear reactors, and for considering the possibility of reprocessing nuclear waste. In recent weeks, the Obama administration has signaled increased support for nuclear power, including the announcement yesterday of the first loan guarantee for new nuclear reactors in the United States.

Current U.S. nuclear power plants are only able to harness as little as 5 percent of the energy in nuclear fuel. Some countries, such as France, use other processes to extract useable nuclear fuel from nuclear waste, but these processes have been criticized, in part because they produce pure plutonium, which could be stolen and used to make nuclear weapons.

GE Hitachi's proposed process would produce fuel that would be more difficult to steal. It separates nuclear waste into three basic groups of materials. The first group consists of the products of fission that can't be used as fuel in nuclear reactors--these will need to be stored, but only for a few hundred years, rather than the tens of thousands of years that other nuclear-waste materials need to be stored. The second group is uranium, which contains too little fissile material to be used in U.S. nuclear reactors, but does contain enough for a type of reactor used in Canada. (Canada's deuterium uranium reactors use deuterium oxide, or heavy water, instead of the light water used in the U.S. as a neutron absorber. Light-water reactors require enriched uranium.)

The last group contains transuranic elements such as neptunium and plutonium. The pure plutonium produced in other processes is relatively easy to handle--it produces little heat and little dangerous radiation. It's also hard to detect, because it doesn't emit many neutrons. These qualities make it a dangerous security risk. But the system that GE Hitachi has designed, which sorts materials by applying a voltage to a molten salt, doesn't separate plutonium from the other transuranic elements. Combined with these other elements, the fuel would release 1,000 times more heat and 10,000 times more gamma rays, so it would be much more difficult to steal, Loewen says.

Indeed, the combination of transuranic elements would likely eventually kill anyone who attempted to take it, he says. Although this wouldn't stop terrorists willing to die to get it, the material also releases 1,000 times more neutrons than pure plutonium, making it far easier to detect.

Charles Forsberg, executive director of the MIT Nuclear Fuel Cycle Project, agrees that these materials would likely be more difficult to steal than plutonium, but he notes that the processing technology could be dangerous in the hands of a nation wanting to repurpose the materials for weapons rather than power plants.

The plutonium and other elements separated from nuclear waste in the GE Hitachi process can be used in a type of nuclear power plant that has been used in Japan, and that is being built in a few other countries, that uses molten sodium as the coolant, instead of the water used in U.S. nuclear power plants. Sodium-cooled reactors allow neutrons emitted during fission to maintain the high energy levels required to use this fuel. The particular type of reactor GE Hitachi has designed--called PRISM--would be compatible with the mix of elements produced by its separation technology. The technology has not yet been approved for use in the United States. One reason is that sodium metal is highly reactive and requires special safety precautions.

Although it could reduce nuclear waste and provide a valuable fuel source for nuclear power plants, the GE Hitachi technology would not completely eliminate the need for long-term storage, Forsberg says, because perfect separation of the components of nuclear waste isn't possible--there will always be some fraction of the material that needs to be stored for more than 10,000 years.

Click here for the original article